Zebron ZB-Bioethanol GC Columns

Fast Quality Checks for Bioethanol Testing

- Specially designed for fast and accurate bioethanol analysis

- Meet ASTM D5501 requirements - resolve methanol and ethanol from all other denaturant peaks

- Great resolution of fusel alcohols

- Allows for quick bake out between runs to eliminate contaminants

Doing biodiesel testing? See ZB-1HT or ZB-5HT.

Recommended Use

Alcohol, Bioethanol, Fusel Alcohols

|

R&D 100 Award-Winning |

Recommended Use Meets ASTM D5501 requirements and resolves methanol and ethanol from all other denaturant peaks |

Upgrade to Zebron from traditional phases used for bioethanol:

| Agilent® | Restek® | SGE® | Supelco® |

|---|---|---|---|

| DB®-1 HP-1 CP-Sil 5 CB |

Rtx®-1 Rxi®-1ms |

BP1 | SPB®-1 SE-30 |

Zebron ZB-Bioethanol

- Resolve methanol and ethanol from all other denaturant peaks

- With analysis time down to 5 minutes, complete certificate of analysis (COA) before fuel truck leaves

- Major cost savings over the standard 100 meter GC columns

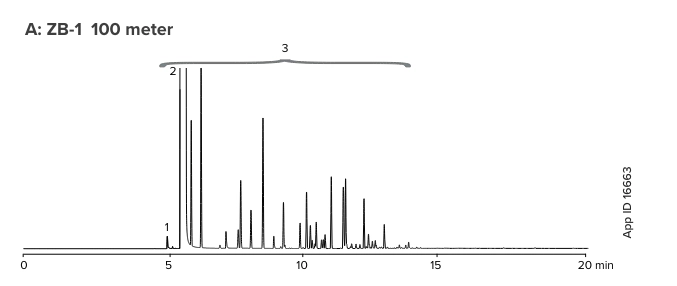

ASTM Method D 5501: Determination of Denatured Bioethanol

|

Column:

Zebron ZB-1

|

|

Dimension:

A) 100 meter x 0.25 mm x 0.50 µm

|

|

Part No.:

7MG-G001-17

|

|

Injection:

Split 50:1 @ 300 °C, 1 µL

|

|

Carrier Gas:

Helium @ 35 cm/sec (Constant Flow)

|

|

Oven Program:

45 °C for 7 min to 255 °C @ 30 °C/min

(Hold 6 min) |

|

Detector:

FID @ 300 °C |

|

Instrument:

Shimadzu® GC-2010 with Flame Ionization

Detection and AOC-20i Automatic Liquid |

|

Sample:

1. Methanol2. Ethanol 3. Denaturant |

ASTM Method D 5501: Determination of Denatured Bioethanol

|

Column:

Zebron ZB-Bioethanol

|

|

Dimension:

B) 30 meter x 0.25 mm x 1.00 µm

C) 15 meter x 0.25 mm x 1.00 µm |

|

Part No.:

B) 7HG-G020-22

C) 7EG-G020-22 |

|

Injection:

Split 50:1 @ 300 °C, 1 µL

|

|

Carrier Gas:

B) Hydrogen @ 35 cm/sec (Constant Flow)

C) Hydrogen @ 25 cm/sec (Constant Flow) |

|

Oven Program:

B) 45 °C for 2.5 min to 255 °C @ 30 °C/min

(Hold 4.5 min)

C) 55 °C for 1.7 min to 260 °C @ 40 °C/min (Hold 2.67 min) |

|

Detector:

FID @ 300 °C |

|

Instrument:

Shimadzu® GC-2010 with Flame Ionization

Detection and AOC-20i Automatic Liquid |

|

Sample:

1. Methanol2. Ethanol 3. Denaturant |

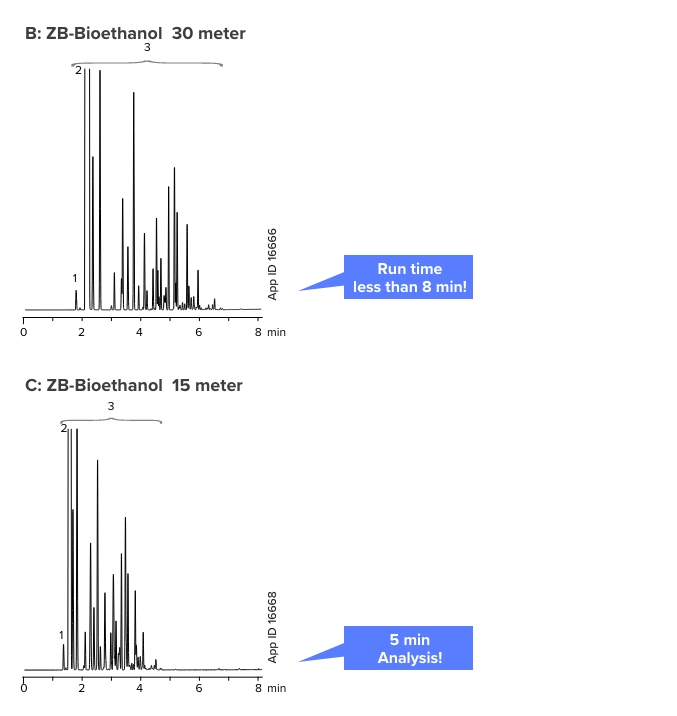

Great Resolution of Fuel Alcohols Products

Since gasoline is a very complex mixture and contains many low boiling components that could potentially co-elute with methanol and ethanol, the resolution provided by the Zebron™ ZB-Bioethanol column was confirmed using GC-MS. As you can see, the methanol and ethanol peaks are well resolved from all potential interferences.

|

Column:

Zebron ZB-Bioethanol

|

|

Dimension:

30 meter x 0.25 mm x 1.00 μm

|

|

Part No.:

7HG-G020-22

|

|

Injection:

Split 100:1 @ 240 °C, 0.1 μL

|

|

Carrier Gas:

Helium @ 1.2 mL/min (Constant Flow)

|

|

Oven Program:

40 °C for 5 min to 300 °C @ 25 °C/min

|

|

Detector:

MSD @ 230 °C; 30 - 450 amu |

Sample:

1. Methanol 2. Ethanol 3. Acrolein 4. Acetone 5. 2-Methylbutane 6. Isopropyl alcohol 7. Pentane 8. t-Butanol 9. Allyl alcohol 10. n-Propanol 11. 2,3-Dimethylbutane 12. 2-Methylpentane 13. 3-Methylpentane 14. 2-Butanol 15. Ethyl acetate 16. Hexane |

Sample:

17. Methylcyclopentane 18. 2,4-Dimethylpentane 19. Benzene 20. Cyclohexane 21. 2-Methylhexane 22. 2,3-Dimethylpentane 23. 3-Methylhexane 24. 2,2,4-Trimethylpentane 25. Heptane 26. Acetal 27. Toluene 28. Xylene 29. Trimethylbenzene |

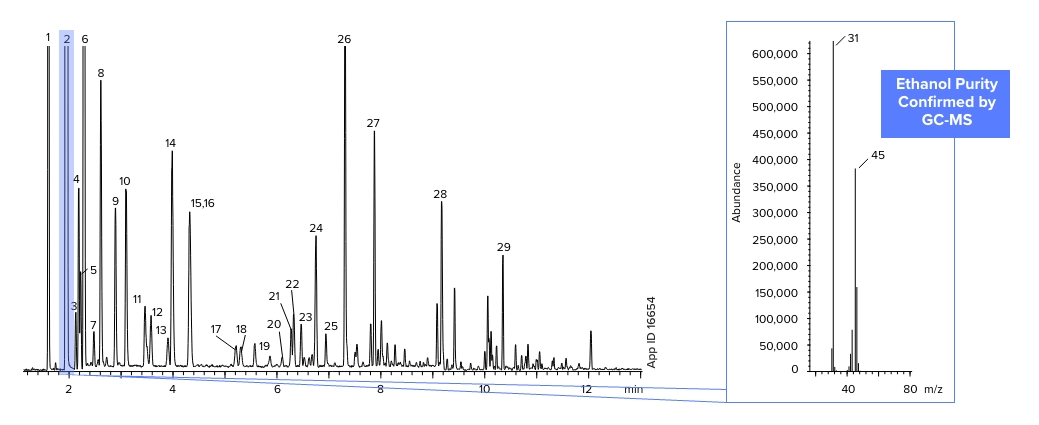

Compatible with Various Carrier Gases

As competition in the biofuels market increases, the need to reduce costs while maintaining quality is of major concern. The shortages of helium and its increasing costs have forced many labs to consider using alternative gases such as hydrogen.

The Zebron™ ZB-Bioethanol column is compatible with all carrier gases and will provide great separation no matter which gas you choose. To verify this, we ran several denatured fuel ethanol samples using various carrier gases. The results were virtually the same regardless of the carrier gas, proving the selectivity provided by the Zebron™ ZB-Bioethanol was not affected.

No resolution changes using different carrier gases

|

Column:

Zebron ZB-Bioethanol

|

|

Dimension:

15 meter x 0.25 mm x 1.00 μm

|

|

Part No.:

7EG-G020-22

|

|

Injection:

Split 50:1 @ 300 °C, 1 μL

|

|

Carrier Gas:

A) Hydrogen @ 25 cm/sec (Constant Flow)

B) Helium @ 25 cm/sec (Constant Flow) |

|

Oven Program:

55 °C for 1.7 min to 260 °C @

40 °C/min (Hold 2.67 min)

|

|

Detector:

FID @ 300 °C |

|

Instrument:

Shimadzu® GC-2010 with a AOC-20i Automatic Liquid Handler |

|

Sample:

1. Methanol2. Ethanol 3. Denaturant |